⚙️⚡⚡ Basic Intro to CNC programming YouTube

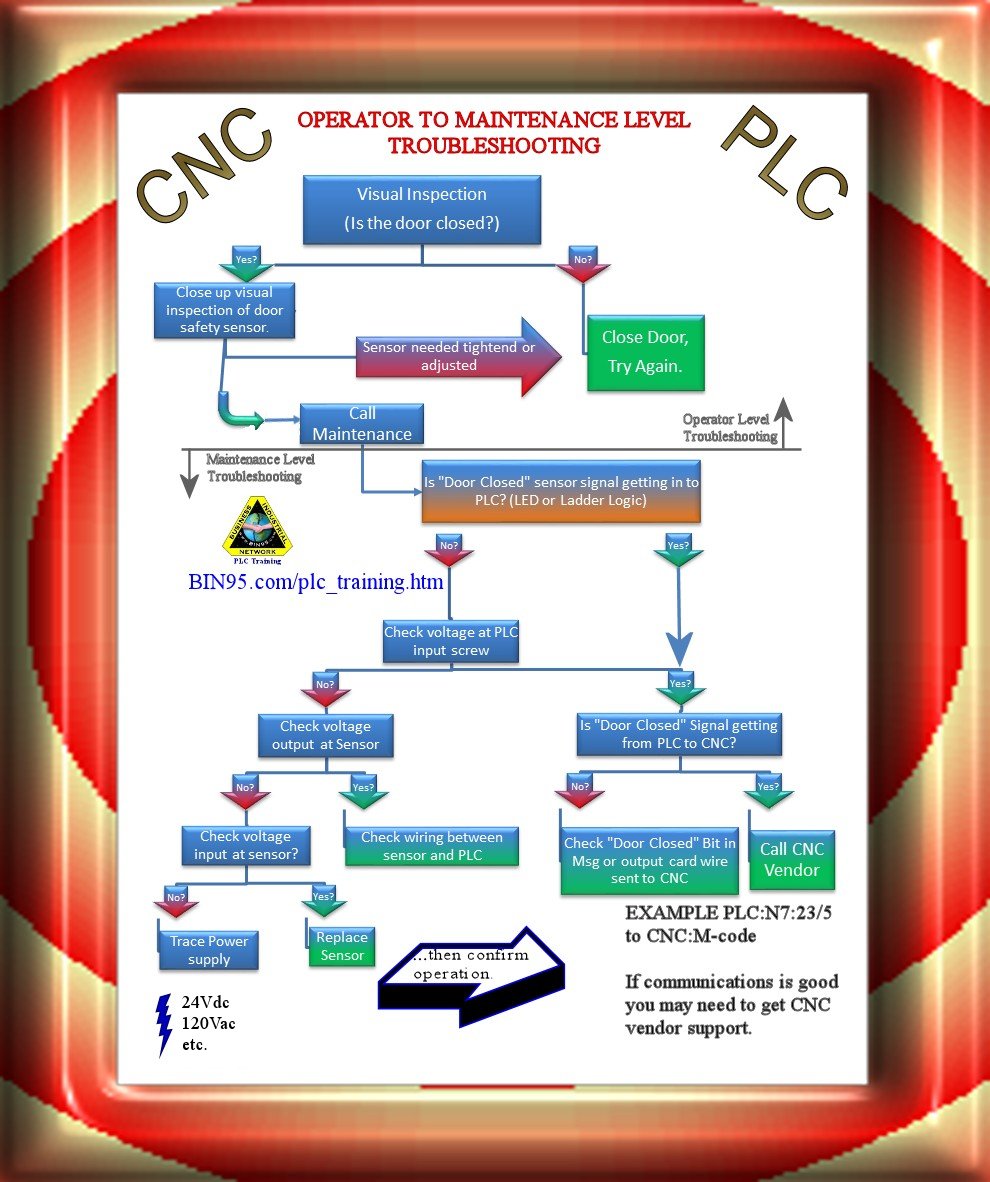

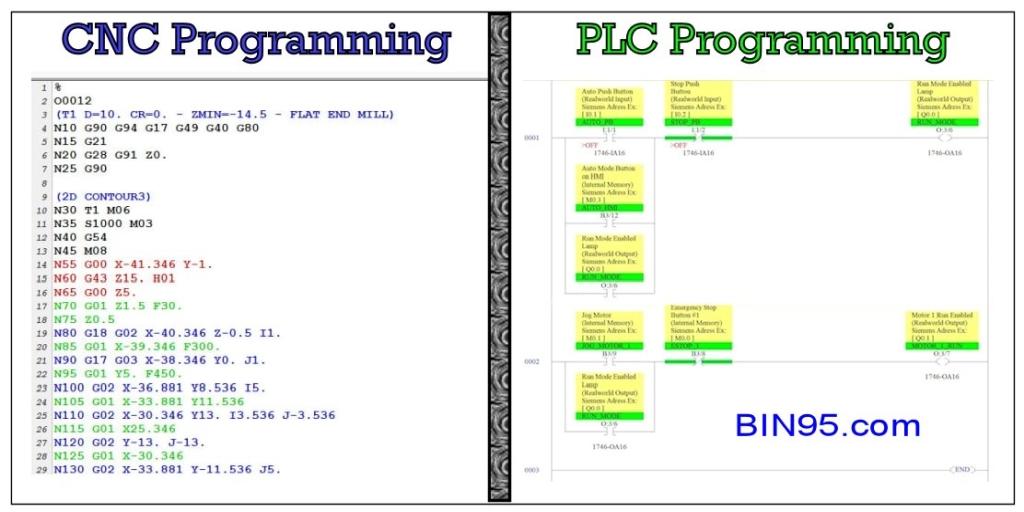

The PLC Program is what is written to describe how the PLC reacts to the Inputs and when to cause Outputs to turn on or off. This manual is for anyone trying to change or write a PLC program on a Centroid CNC11 or CNC12 system. A CNC11 system is one that is based on MPU11 hardware, while a CNC12 system is one that is based on MPU12 hardware.

CNC PLC Programming

GSK983M(T) CNC System PLC Program Manual 4 1.4 Sequence Program Maximum Steps In the GSK983M/ T NC's PLC, the maximum steps number is 2000. 2 NC Signal Address PLC 2.1 Signals Class In the GSK983M/ T NC system, the signals classes: 1) Input to PLC from MT signals. 2) Input to PLC from CNC signals. 3) Output from PLC to CNC signals.

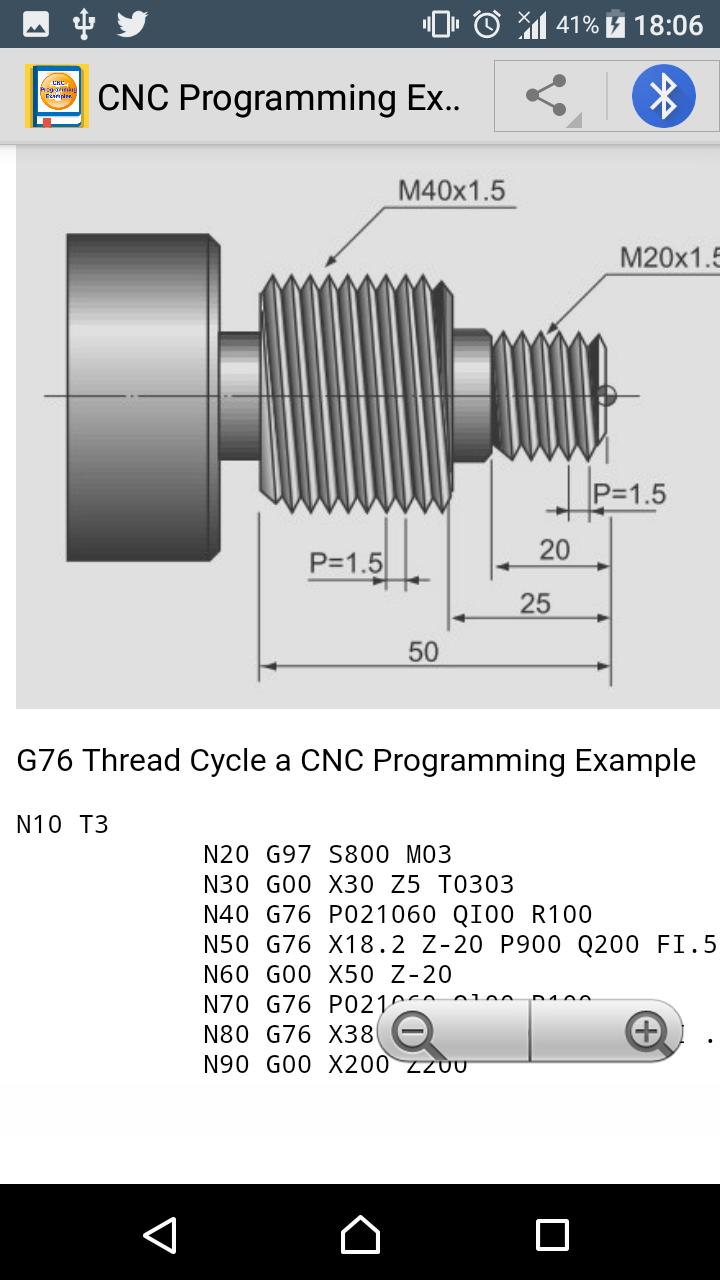

CNC Programming Examples APK for Android Download

Preface CNC Commissioning: NCK, PLC, drive 4 Commissioning Manual, 02/2012, 6FC5397-2AP40-3BA0 SINUMERIK You can find information on SINUMERIK under the following link:

Cnc Programming

2. PLC Processing Program 2.1 PLC Processing Program Level and Operation Table 2.1-1 explains the contents of users PLC processing level and Fig. 2.1-1 shows the timing chart. Table 2.1-1 PLC processing level Program name Description (frequency, level, etc.) High-speed processing program This program starts periodically with a time interval of.

An Intro to CNC Machine Programming Resources Fast Radius

These specifications are the programming manual used when creating the sequence program with the PLC development software, or Mitsubishi Electric Co.'s integrated FA software MELSOFT series (GX Developer). The PLC (Programmable Logic Controller) is largely divided into the basic commands,

Cnc Programming

Level0-Level5, PLC programming Languages - ladder(LD), function block (FBD), structured text (STL), Sequential Flow Charts (SFC), IEC 61131-3 Programming Standard and PLCOpen Interoperability.

CNC Programming Handbook A Comprehensive Guide to Practical CNC Programming [With CDROM] by

CNC Commissioning: NC, PLC, Drive Commissioning Manual Valid for: SINUMERIK 840D sl/840DE sl CNC software Version 4.93 12/2019 A5E48312804B AA Preface Fundamental safety instructions 1 Introduction 2 Requirements for commissioning 3 Licensing 4 PLC commissioning 5 Commissioning NC-controlled drives 6 Communication between the NC and the drive 7

Cnc Programming

9/Series PALReference Manual Index(General) 9/Series Mill Tableof Contents Operation and Programming Manual v 10.4.1 Minimumand MaximumAxis Motion (Programming Resolution) 10-21

Industrial Skills Training CNC PLC Programming

In part A, use the NUM PLC toyou will practice exchanging information between the PLC and the programming of logic sequences on CNC. In part B, you will practice the NUM PLC. Part A: CNC-PLC Communication . It is possible using the PLC program to read some data from the CNC and control the CNC's functions and/or

An Intro to CNC Machine Programming Fast Radius

PLC Function Manual Valid for Control system SINUMERIK 840D sl / 840DE sl CNC software version 4.92 06/2019 A5E47433877B AB Preface Fundamental safety instructions 1 Overview 2 PLC mode selector 3 Reserve resources (timers, counters, FC, FB, DB, I/O) 4 Commissioning hardware configuration of the PLC CPU 5 Starting up the PLC program 6 Coupling.

CNC vs PLC What Do They Stand For and What Is The Difference? Do Supply Tech Support

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation

Basics of CNC Programming

Here's what we have for CNC Programming PDF's: CNC Machine Programming Course / PDF eBook Includes examples, Fanuc dialect, and more. Learn to read and write g-code in this 16 chapter tutorial course and eBook. [ Download PDF ] Download PDF DFMA Course / PDF eBook

Cnc Programming Examples Turn And Mill Cnc Training Centre Gambaran

Commissioning the PLC program 4 Handling of blocks and libraries 5 Inserting the PLC basic program into the project 6 Specifying the execution structure and OBs of the PLC program 7 PLC-NC interface 8 NC process alarms 9 Reference on the PLC basic program 10 Appendix A Valid for: Control system SINUMERIK MC Software CNC software version 1.12.

What Is CNC Programming? Unity Manufacture

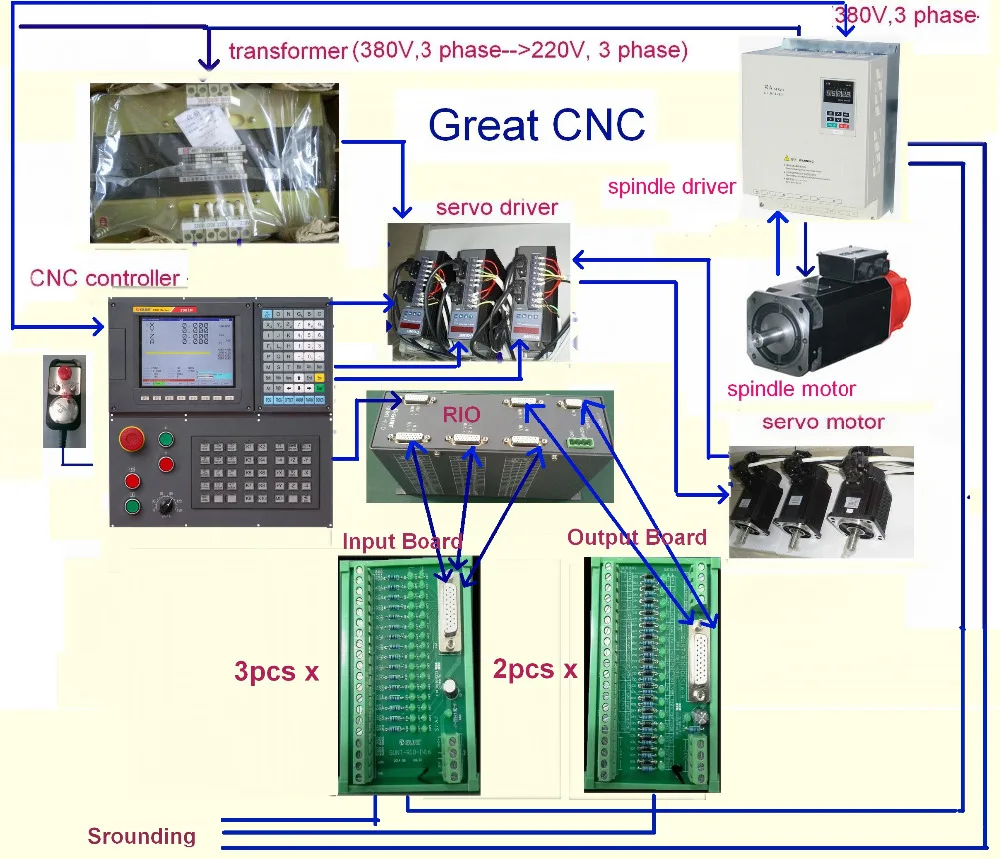

1. PLC DEVELOPMENT ENVIRONMENT 1.1 System Configuration Most of the development work can be done by connecting a personal computer and a CNC unit by an RS-232C cable. [Note] The supported peripheral devices and like change depending on the model. ROM cassette Data save PLC program editing Floppydisk drive unit DOS format FLD IC card Ladder monitor

CNC PROGRAMMING MILLING atelieryuwa.ciao.jp

This product uses the following source code, subject to the terms of the GPL license. The applications busybox V0.60.2; dosfstools V2.9; linux-ftpd V0.17; ppp V2.4.0; utelnet V0.1.1. The library grx V2.4.4. The linux kernel V2.4.4.

CNC System Kit,Milling/Engraving PLC Motion CNC Controller Package;17bit Absolute Encoder Motor

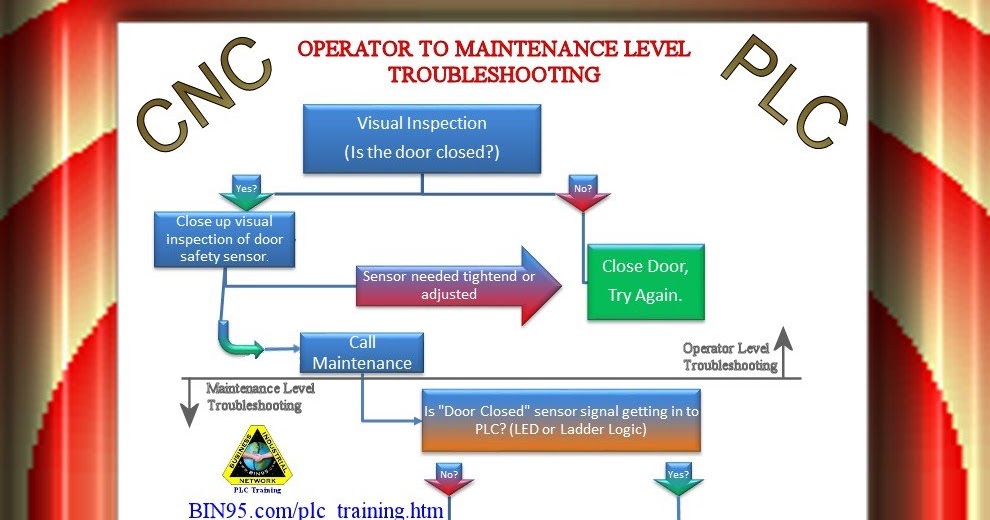

The Centroid PLC or Programmable Logic Controller is responsible for controlling outputs primarily based upon the state of inputs, but also for controlling outputs based upon time. The Centroid PLC Program itself is the logic that is written to describe how the Centroid CNC PLC reacts to the Inputs and when to cause Outputs to turn on or off.